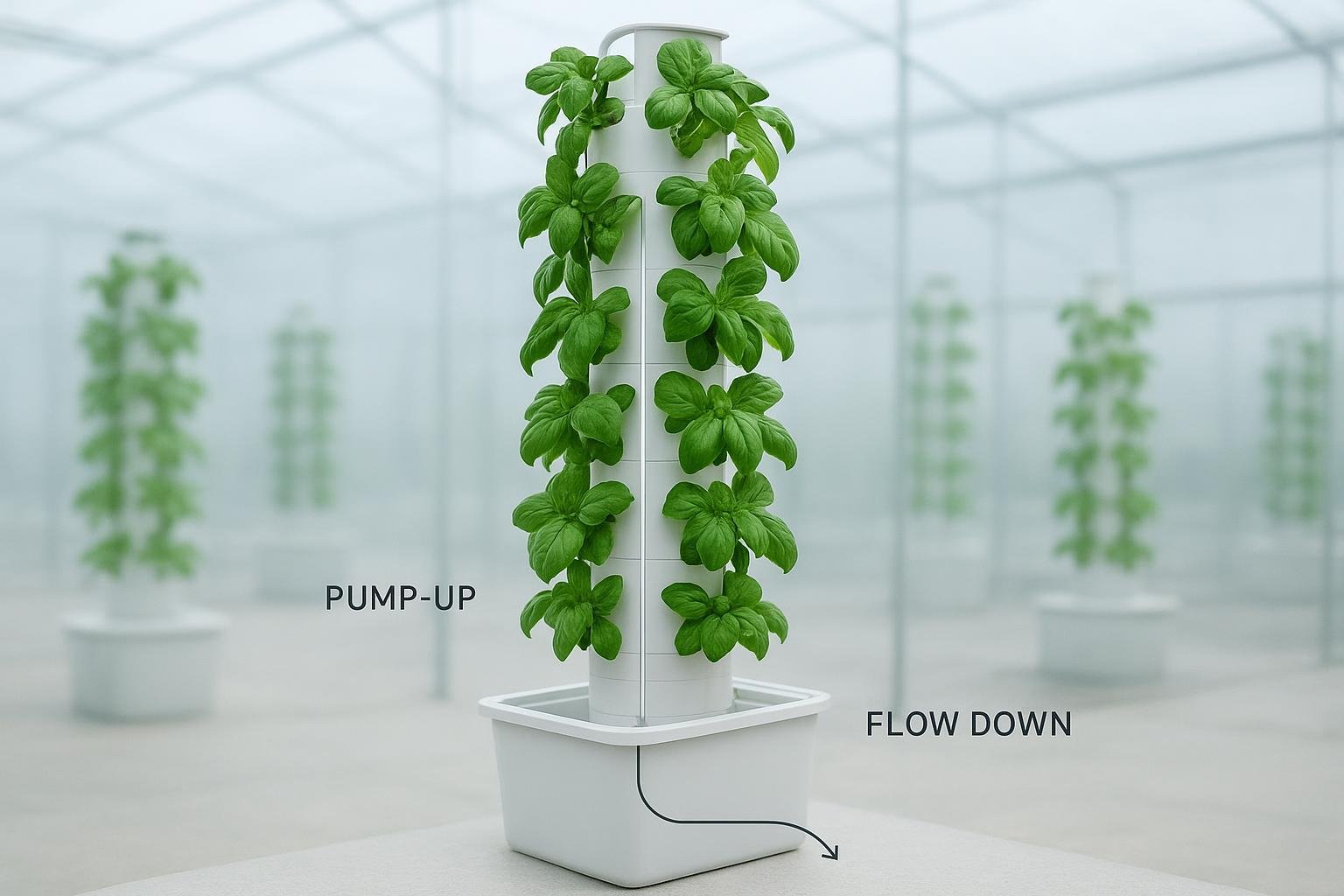

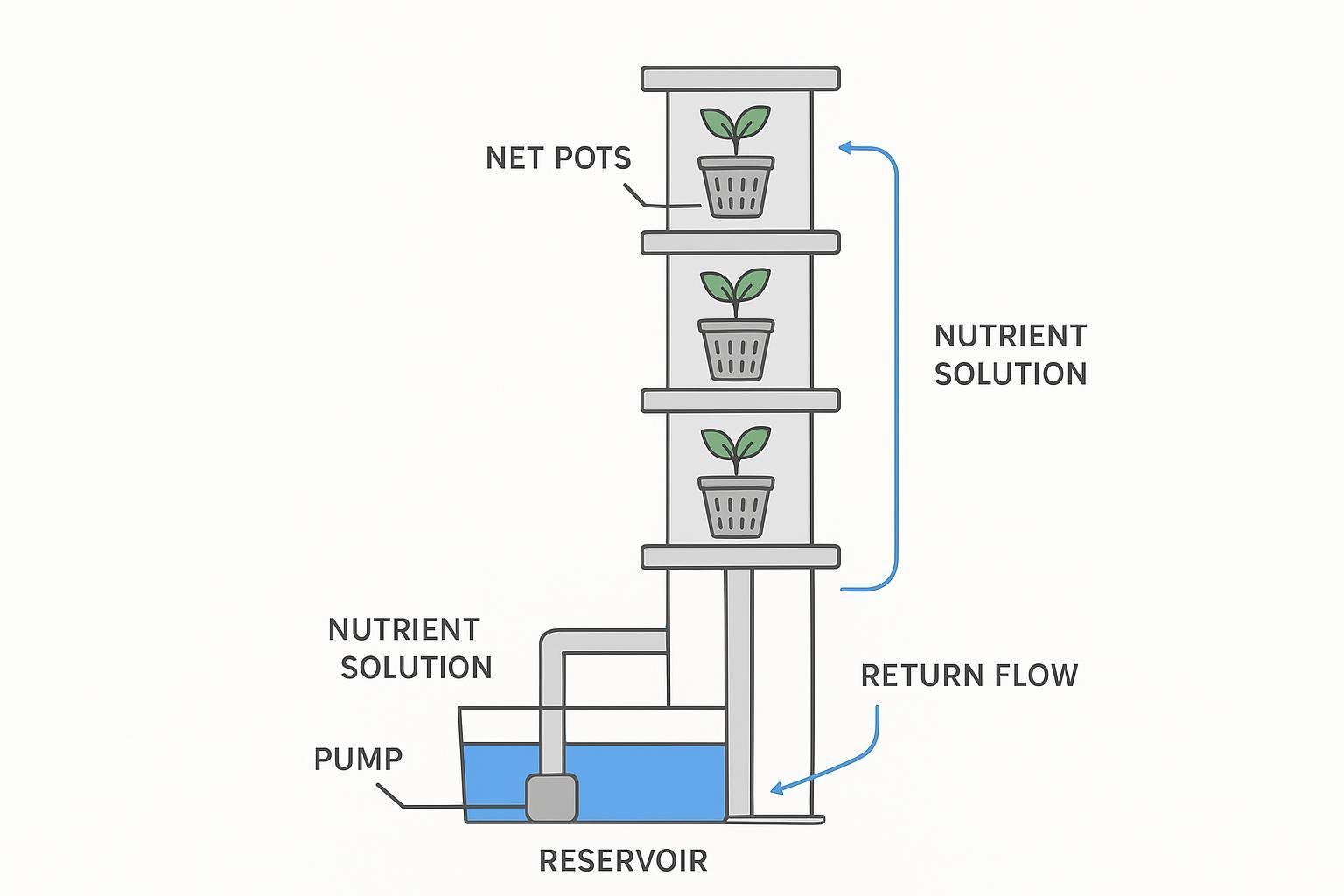

A Hydroponic Tower is a vertical, soil-free growing system that arranges many plant sites along a column and feeds their roots with a recirculating, nutrient-rich water solution. A submersible pump lifts the solution from a base reservoir to the top; gravity then distributes it down past each plant site, returning the unused solution back to the reservoir. By stacking plants vertically, the tower increases output per unit floor area and fits both Indoor Hydroponics and greenhouse applications.

Key Takeaways

-

A Hydroponic Tower is a vertical, closed-loop system for Soil-free Gardening that recirculates a nutrient solution from a reservoir up to the top and back down past plant roots.

-

Typical crops include leafy greens, herbs, and strawberries; heavier or vining crops need special support and are less common in towers.

-

Evidence from university extensions and peer-reviewed literature indicates high water-use efficiency (often ~90% less water than soil systems) and strong space utilization, especially for Vertical Farming.

-

Towers can run in greenhouses or indoors; indoor deployments require attention to lighting (PPFD), airflow, and humidity.

-

Routine SOPs—pH/EC monitoring, sanitation, and pump/tubing checks—keep systems stable for Hydroponic Gardening at home or commercial scale.

How a Hydroponic Tower Works

Think of a Hydroponic Tower like a multi‑storey apartment for roots, with a rooftop plumbing line. The system’s reservoir holds a nutrient solution. A small submersible pump sends that solution up through tubing to the top of the tower. From there, gravity lets a thin film or drip trickle down through the column, bathing each plant’s root zone before the solution returns to the reservoir. Because the solution is reused (closed loop), water losses to runoff and evaporation are minimized compared to soil.

According to Oklahoma State University Extension, vertical hydroponic towers can provide more than 90 percent efficiency in water use due to recirculation and reduced losses, framed as advantages over traditional methods in their tower guidance (2021) — see OSU’s “Building a Vertical Hydroponic Tower” factsheet. UF/IFAS resources describe towers as closed-loop systems that save space and suit urban settings, highlighting pump-to-top and gravity-down mechanics (2025) — see UF/IFAS’s vertical tower overview.

Components of a Hydroponic Tower

Below are the common parts you’ll encounter in a tower system.

-

Reservoir: Opaque tank that stores the nutrient solution and reduces algae.

-

Submersible pump: Moves solution from reservoir to the tower top; often controlled by a timer.

-

Tower modules: Vertical sections with staggered plant ports to reduce shadowing.

-

Net pots and inert media: Mechanical support for plants (e.g., mineral wool, perlite); roots access flowing solution.

-

Tubing and delivery fittings: Carry solution upward; distribute drip/film down the column.

-

Optional timer/controller: Automates pump cycles and schedules.

-

Basic sensors: Handheld pH and EC meters for routine checks; dissolved oxygen (DO) sensors are optional in advanced setups.

Delivery Methods in Tower Systems

Hydroponic towers use one of several delivery methods, each with trade-offs you’ll want to understand.

-

Drip/trickle: The simplest approach. Solution percolates through media or contact surfaces. It’s energy‑light and forgiving. Substrates like mineral wool or perlite provide air space that helps root oxygenation. Extension resources outline these media characteristics — see OSU’s soilless media overview.

-

Tower‑style NFT (thin film): A shallow film flows over roots. Efficient and uniform, but more sensitive to flow interruptions and clogging. If the pump stops, roots can quickly stress.

-

Aeroponic mist: Nozzles spray fine mist onto roots. Oxygenation is highest, and growth rates can be strong, but system complexity and maintenance (nozzle clogging, high‑pressure pumps) are greater. Peer‑reviewed work outlines aeroponic advantages and sensitivities — see the 2023 hydroponics review synthesizing water savings and aeroponics system analyses (e.g., Frontiers‑indexed reviews on aeroponics mechanics).

Hydroponic Gardening and Vertical Farming Fit

Hydroponic towers sit squarely within Hydroponic Gardening and are a practical format for Vertical Farming because they stack plant sites to amplify plants per square foot. Peer‑reviewed literature indicates hydroponic systems can reduce water use by up to ~90% compared with soil by recycling nutrient solutions, a principle directly applicable to closed‑loop towers — see the 2023 synthesis on hydroponics sustainability. Closed‑loop approaches outperform open systems for water‑use metrics in multiple crops — see the Canadian Journal of Plant Science perspective (2023). These efficiencies make towers attractive for Soil-free Gardening in land‑limited urban spaces.

Indoor Hydroponics Lighting Guide

For Indoor Hydroponics, lighting determines consistency. Many leafy greens and herbs perform well in the medium PPFD range of roughly 150–250 µmol/m²/s with 12–14 hours of light per day, and fixture heights around 6–12 inches depending on optics. That’s consistent with university guidance — see University of Minnesota Extension’s PPFD recommendations (2020). When you scale towers, watch uniformity: lower tiers often need side lighting or reflective surfaces to avoid shading.

System Comparisons

|

System |

Space Efficiency |

Best‑Fit Crops |

Maintenance Complexity |

Failure Sensitivity |

Scalability |

|---|---|---|---|---|---|

|

Hydroponic Tower |

High (vertical stacking) |

Leafy greens, herbs, strawberries |

Moderate (pump, sanitation, pH/EC) |

Pump outages, clogging |

Modular columns; good for dense footprints |

|

NFT Channels |

Medium–High |

Leafy greens, small herbs |

Moderate (channel cleaning, flow checks) |

High if flow stops |

Scalable in racks or gutters |

|

DWC (Raft) |

Medium |

Leafy greens |

Low–Moderate (aeration, sanitation) |

Aeration failure risk |

Scales in benches/tanks |

|

Ebb‑and‑Flow |

Medium |

Greens, some fruiting with substrate |

Moderate (flood cycle tuning, media care) |

Timer/pump failures |

Scales on tables/trays |

Maintenance SOP Checklist

Reliable Hydroponic Gardening depends on routine care. Here’s a concise SOP you can adapt to home or commercial contexts.

-

Daily: Visual check pump operation and flow; confirm water level; inspect for leaks, clogged emitters, and abnormal plant wilting.

-

Weekly: Measure and log pH (target ~5.8–6.2 for many greens) and EC (e.g., ~1.3 dS/m for lettuce in film/trickle systems). Adjust with acid/base and nutrients as needed. Guidance aligns with extension sources — see Purdue’s lettuce EC recommendation and Ohio State’s nutrient solution parameters.

-

Biweekly to Monthly: Refresh or replace a portion of the reservoir solution depending on crop load and measurements; top off regularly to maintain volume.

-

Monthly or Between Crop Cycles: Sanitize tower modules, reservoir surfaces, and tubing to reduce algae and pathogens. Extension resources offer practical sanitation notes — see OSU’s algae control guidance and UMN’s small‑scale hydroponics guide.

-

Quarterly: Inspect pumps, tubing, and fittings; replace wear items; consider a spare pump on hand for redundancy.

Common Pitfalls and Fixes

-

Lower‑tier shading: Add side lighting or reflective films; adjust plant spacing and prune larger leaves.

-

Pump failure: Use a backup pump and an alert (simple plug‑in alarm or controller notification). Test alarms monthly.

-

Clogging and biofilm: Keep filters clean; flush lines; sanitize between cycles; select emitters compatible with your nutrient mix.

-

Nutrient imbalance: Track pH/EC weekly; avoid over‑concentrating solution; calibrate meters monthly.

Practical Example Using a Commercial Tower

Disclosure: SPRINGS FAITH is our product.

In a small greenhouse array (e.g., 10 towers, ~25–30 plant sites each), a neutral SOP might schedule a daily pump check at opening and an evening pH/EC log, with a biweekly reservoir refresh and monthly sanitation. Commercial‑grade tower designs support opaque reservoirs to limit algae, staggered plant ports for better light, and accessible plumbing for quick emitter inspection. This workflow aligns with the principles above and is typical of Vertical Farming configurations where footprint and stability matter.

Who Should Use a Hydroponic Tower

-

Commercial greenhouse/vertical farm teams: Fit when floor space is tight and crop mix favors leafy greens, herbs, or strawberries.

-

Urban farm developers and ag engineers: Useful in land‑constrained projects; closed‑loop recirculation supports water budgets and compliance goals.

-

Home Indoor Hydroponics enthusiasts: Compact, modular towers provide a clear path into Soil-free Gardening with predictable routines.

Final Thoughts and Next Steps

A Hydroponic Tower is a practical, space‑efficient way to grow soilless crops using a recirculating nutrient solution. If you’re evaluating towers for a greenhouse, urban farm, or indoor setup, review your crop list, lighting plan, and maintenance capacity, then match delivery method and module design accordingly. To explore engineering specs or discuss configuration options for commercial or home towers, you can reach out for technical documentation and planning support.