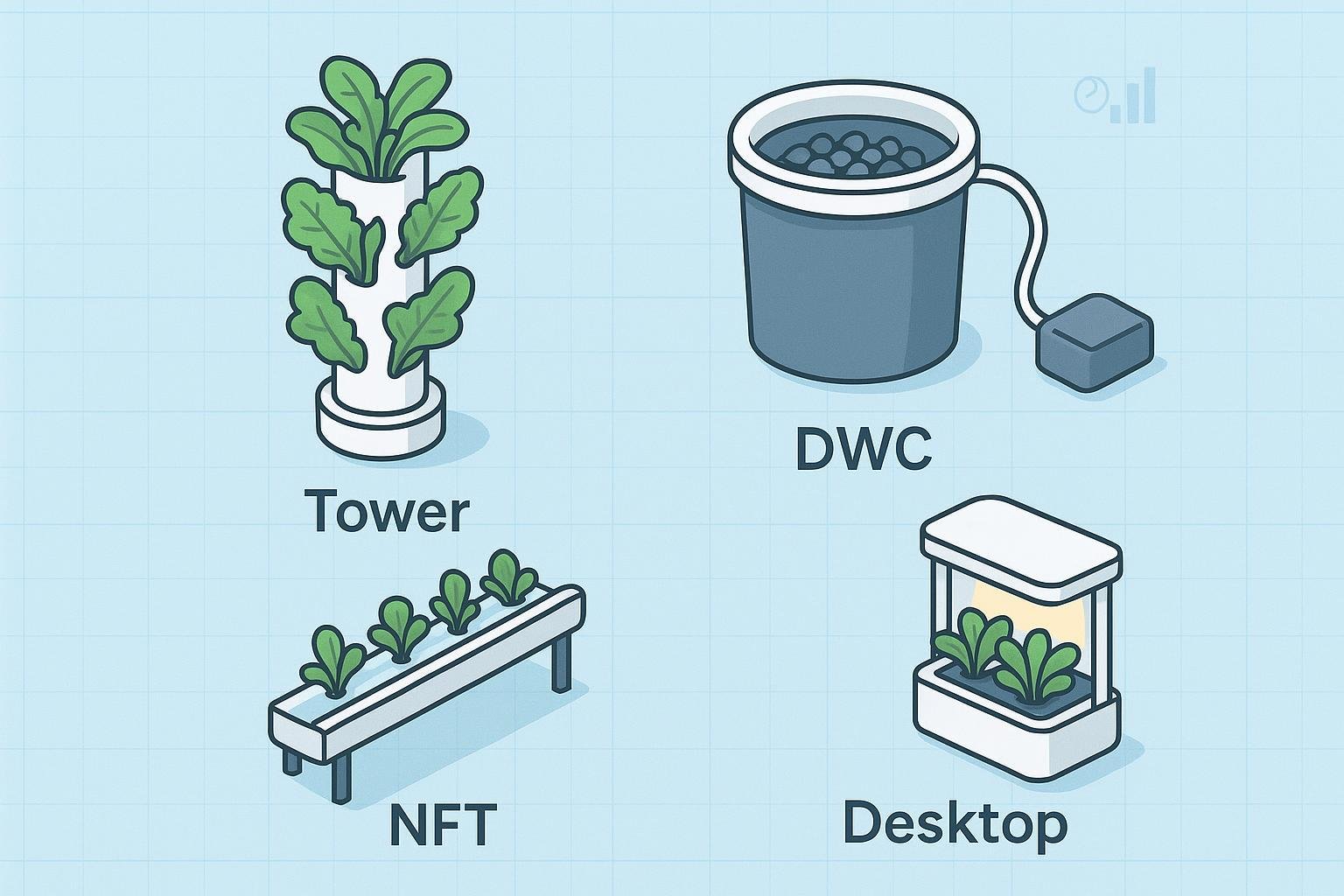

If you’re planning a 30 m² indoor micro-farm for leafy greens and herbs, choosing the right indoor hydroponic system kit determines how much you’ll harvest per square meter, how often batches pass quality checks, and how many hours your team spends on changeovers and maintenance. This comparison focuses on four kit categories—tower, deep water culture (DWC), nutrient film technique (NFT), and desktop/countertop—through three primary metrics: unit-area yield, batch pass rate, and monthly maintenance hours. Secondary lenses include energy/ROI predictability, modular scalability, and system stability & food safety SOPs.

Key takeaways

-

Tower kits generally win on footprint efficiency and water-smart recirculation, offering strong plants-per-m² and predictable workflows; sanitation needs careful SOPs.

-

DWC kits are simple and robust at small scale, but maintenance scales linearly with bucket count; oxygenation quality drives pass rates.

-

NFT kits can reach high planting density, yet require stable flow, regular filter checks, and disciplined cleaning to avoid clogs and biofilm.

-

Desktop/countertop systems are low-labor pilots and education tools; they don’t scale for commercial yields but offer clear energy predictability.

-

For a 30 m² micro-farm, towers and NFT racks often deliver the best yield/m²; DWC can underpin specific crops; desktops fit training or herb modules.

At-a-glance comparison table — indoor hydroponic system kit categories

Below is a decision-oriented snapshot using representative models and transparent assumptions. Where official specs are missing, ranges are noted and no definitive values are claimed.

|

Category |

Representative models |

Plant capacity (per unit) |

Footprint efficiency (plants/m²) |

Indicative yield (kg/m²/month) |

Batch pass rate drivers |

Maintenance hours/month (typical per unit) |

Energy notes |

Scalability |

SOP complexity |

|---|---|---|---|---|---|---|---|---|---|

|

Tower |

Lettuce Grow Farmstand Nook; Gardyn Home Kit 3.0; Aerospring 27-Plant |

20–30–27 |

~50–70 (vertical footprint) |

~3.0–5.0 (lettuce, typical ranges) |

Stable recirculation and uniform lighting; sanitation of internal surfaces |

~2–4 (weekly wipe-downs, monthly deep clean) |

LED duty 12–16 h/day; pump intermittent/continuous depending on kit |

Modular stacking/arrays |

Medium — internal plumbing cleaning and CIP logging |

|

DWC |

VIVOSUN 5-Gal 2-bucket; Mars Hydro 5–7 Gal; General Hydroponics multi-site |

1–2 sites/bucket |

~8–12 (space-heavy) |

~1.5–2.5 |

Dissolved oxygen and temperature stability; clean air stones |

~3–6 (per 2–4 buckets) |

Air pump 7–16 L/min; lights vary; energy predictable per bucket |

Scales linearly with buckets |

Low–Medium — bucket sanitation is straightforward |

|

NFT |

EEWA HDPE channels; 108-hole PVC kits; DIY downspout NFT |

32–108+ sites/rack |

~80–120 |

~3.5–5.5 |

Film stability, filter hygiene, algae control |

~3–5 (per rack) |

Small pump continuous flow; lights per rack |

Link channels; pooled reservoirs |

Medium — channels require regular flushing |

|

Desktop |

AeroGarden Harvest; Click & Grow SG9; LetPot Mini/Air/Lite |

5–9–12+ pods |

~100–150 (tiny footprint, low canopy) |

~0.8–1.2 |

Simple pods; consistent light cycles; food-contact sanitation |

~0.5–1.5 |

10–36W LEDs; very predictable |

Poor — best for pilots/education |

Low — simple wipe/sanitize routines |

Notes: Yield ranges are proxies based on plant density and typical cycle durations for lettuce and basil; adjust for actual cultivars and environment.

Tower hydroponic system kits — footprint efficiency and water-smart recirculation

Tower systems pack many plants into a small footprint and recirculate nutrients efficiently, which is attractive in land-constrained urban spaces. For example, the compact Farmstand Nook lists 20 plant sites in a footprint under ~4 sq ft and an integrated 9-gallon reservoir, according to the manufacturer’s “Meet the Farmstand Nook” overview as of 2026. See the official Nook page for capacity and dimensions: the manufacturer’s site confirms 20 plants and 18.6″ diameter with integrated lighting, though detailed wattage isn’t publicly disclosed on that page. Source: the brand’s Nook overview page and help-center guidance on footprint positioning: “Meet the Farmstand Nook” and “Finding the best spot for your Farmstand.”

-

Lettuce Grow Farmstand Nook overview: the manufacturer’s page lists a 20-plant capacity and compact footprint; electrical specs for the lights were not found on that page as of Jan 2026. Manufacturer overview. Guidance on placement and footprint comes from the brand’s help center. Help-center footprint guidance

Aerospring publishes a complete specification set for its 27-Plant Vertical Hydroponic System—27 plant sites, 24″ × 24″ × 72″ dimensions, a 17-gallon reservoir, and an EcoPlus submersible pump, with optional LED kits where wattage is clearly listed on the official page. This transparency helps with energy predictability. Aerospring official product page

Gardyn’s Home line indicates up to 30 plants and a footprint under ~2 square feet, with a 3-gallon fill reference in its help center. However, consolidated wattage, pump specs, and current MSRP are not clearly presented on the pages reviewed. Gardyn Home overview and Help center 3-gallon reference

How towers perform on our three primary metrics:

-

Unit-area yield: High. With 50–70 plants/m² common for compact towers, lettuce yields of ~3.0–5.0 kg/m²/month are achievable under typical cycles (28–35 days) and good lighting.

-

Batch pass rate: Generally strong if sanitation is disciplined. Internal plumbing and surfaces need regular cleaning to prevent biofilm and off-flavors.

-

Maintenance hours: Moderate. Expect weekly wipe-downs and monthly deep cleans—roughly 2–4 hours/unit/month—plus routine nutrient checks.

Secondary lenses:

-

Energy/ROI predictability: Good when wattage and duty cycles are known (e.g., Aerospring’s optional LED specs). Missing electrical specs (e.g., some tower lights) complicate modeling.

-

Modularity & scalability: Strong; towers can be stacked or arrayed to scale a 30 m² room efficiently.

-

System stability & food safety: Recirculation stability is a plus; food-contact surfaces and internal plumbing increase SOP importance.

DWC kits — oxygenation, simplicity, and linear maintenance scaling

DWC keeps roots submerged in aerated nutrient solution, which is simple to set up and forgiving for beginners. Official manuals for VIVOSUN DWC kits list air pump outputs by kit size (e.g., multi-bucket kits around 60 L/min; small kits roughly 7–16 L/min) and include air stones, tubing, and check valves; bucket capacity commonly sits at 5 gallons. VIVOSUN DWC manual (recirculating drip) and VIVOSUN kit overview

Mars Hydro’s DWC kits similarly specify 5-gallon buckets, 8-inch baskets, and ~7 L/min air pump ratings in certain configurations. Mars Hydro DWC kit page

General Hydroponics’ multi-site modules (e.g., WaterFarm and PowerGrower) use top-feed recirculation with submersible pumps in the ~160–250 GPH range and net pots around 10 inches, offering more sites per controller. Use manufacturer and authorized retailer pages for current specs and pricing. (Add traceable links when finalizing procurement.)

How DWC performs on the three primary metrics:

-

Unit-area yield: Moderate. Buckets consume space; plants/m² are lower than towers/NFT. Expect ~1.5–2.5 kg/m²/month with lettuce under typical cycles.

-

Batch pass rate: Highly dependent on dissolved oxygen (DO), solution temperature, and cleanliness of air stones and lines. Good DO correlates with fewer root issues.

-

Maintenance hours: Scales linearly. Each bucket adds changeover time—biweekly solution changes and periodic air stone checks—~3–6 hours/month for a small cluster.

Secondary lenses:

-

Energy/ROI predictability: Strong. Air pumps have predictable wattage; lights are straightforward to model.

-

Modularity & scalability: Linear scaling with buckets; manifolds and controller reservoirs help but add complexity.

-

System stability & food safety: Buckets are easy to sanitize; keep lids, tubing, and stones clean to reduce contamination risk.

NFT kits — high-density channels with flow stability requirements

NFT runs a thin film of nutrient solution through channels where roots sit. It can achieve high planting density and excellent footprint efficiency, but it requires stable flow and clean channels to avoid clogs and dry spots.

EEWA Farms’ 4 m HDPE NFT channels are food-safe components with a recommended 2–4 L/min per channel flow rate and standardized profiles (100 × 50 mm). Their small indoor kits illustrate channel counts and reservoir sizing for compact racks. EEWA HDPE NFT channel spec and kit examples: 32-plant wall kit and 64-plant balcony rack

Generic 108-hole PVC NFT kits published on consumer marketplaces show layouts (e.g., 12 pipes × 3 layers = 108 holes) but often lack authoritative flow and materials safety documentation—use caution for commercial deployments. Example layout reference

How NFT performs on the three primary metrics:

-

Unit-area yield: High, similar or superior to towers if managed well. Ranges of ~3.5–5.5 kg/m²/month are typical for lettuce under disciplined operations.

-

Batch pass rate: Sensitive to flow uniformity and filtration. Biofilm and algae must be controlled to keep holes unclogged and roots wetted.

-

Maintenance hours: Moderate. Expect weekly filter checks and monthly channel flushes—~3–5 hours/month per rack.

Secondary lenses:

-

Energy/ROI predictability: Good. Small pumps run continuously; wattage is stable and easy to forecast.

-

Modularity & scalability: Strong. Channels can be linked with pooled reservoirs; ensure balanced flow distribution.

-

System stability & food safety: Channels are food-contact surfaces; schedule routine sanitation and document procedures.

Desktop/countertop kits — low maintenance pilots with limited scalability

Desktop systems are great for demonstrations, culinary herb modules, or training. They deliver predictable energy usage and minimal maintenance—but limited yield.

AeroGarden’s Harvest Elite lists six plant sites and a 20W full-spectrum LED, with compact dimensions and straightforward controls. AeroGarden Harvest Elite product page

Click & Grow’s Smart Garden 9 specifies nine pods, a ~4 L reservoir, and a 13W LED with app reminders—useful for predictable light cycles and basic logging. Smart Garden 9 official page

LetPot’s lineup spans 10–36W LEDs and 1.5–7.5 L reservoirs with app control across models (Mini, Air, Lite, Senior, Max), reinforcing energy predictability. LetPot Mini and LetPot Air

How desktops perform on the three primary metrics:

-

Unit-area yield: Low for commercial goals—~0.8–1.2 kg/m²/month equivalents when extrapolated, due to limited plant mass and canopy.

-

Batch pass rate: Generally high; pods and consistent light reduce variability.

-

Maintenance hours: Minimal. ~0.5–1.5 hours/month for sanitation and pod changes.

Secondary lenses:

-

Energy/ROI predictability: Excellent. LED wattage is explicit; duty cycles are fixed.

-

Modularity & scalability: Poor for commercial yield; suitable as pilot stations or culinary herb corners.

-

System stability & food safety: Simple surfaces and reservoirs—easy to sanitize and log.

30 m² micro-farm scenario: yield, labor, and energy snapshots

Assumptions (transparent and adjustable):

-

Crop: Leafy lettuce; cycle time 30 days (~1 harvest/month). Basil behaves differently (repeat cuts), but we stick to lettuce for clarity.

-

Utility rate: $0.15/kWh.

-

Lighting duty cycle: 16 h/day.

-

Labor rate not used in calculations below; we present hours only.

Indicative outcomes per category (order-of-magnitude to compare planning options):

-

Towers: With ~55 plants/m², a 30 m² space holds ~1,650 sites. At ~0.2 kg/plant/harvest, yield ≈ 330 kg/month. Energy depends on LED kits; as an example, 20W per 6–9 plants is common in desktop scale—tower kits typically use higher wattage per canopy area. If a cluster averages ~400W total lighting over 30 m² (illustrative only), kWh ≈ 0.4 kW × 16 h × 30 d = 192 kWh → ~$28.80/month. Maintenance: ~2–4 hours/unit/month; a 30 m² array may encompass 10–15 towers → ~20–60 hours/month.

-

DWC: Lower plants/m²; assume ~10 plants/m² → ~300 plants. At 0.2 kg/plant, yield ≈ 60 kg/month. Lighting similar per canopy area; air pump loads are modest (e.g., 7–16 L/min at single-digit watts). Maintenance: Bucket changes scale linearly—expect ~30–60 hours/month for a distributed bucket system.

-

NFT: High density; assume ~90 plants/m² → ~2,700 plants. At 0.15–0.2 kg/plant, yield ≈ 405–540 kg/month. Pumps are small but continuous; lighting wattage per canopy area comparable to towers. Maintenance: ~3–5 hours/month per rack; across a room (e.g., 6–10 racks), ~18–50 hours/month.

-

Desktop: Not intended for whole-room production. For a pilot corner (e.g., 10 devices), yield may be ~10–20 kg/month combined, energy ~10–36W per device → 4.8–17.3 kWh/month/device → ~$0.72–$2.60/device/month at our utility rate. Maintenance: ~5–15 hours/month total.

These snapshots are proxies to help shortlist categories. Validate with your specific device wattages and actual plant mass data.

Sensitivity (quick): PPFD 100–200 µmol·m⁻²·s⁻¹ (DLI ≈12–20 mol·m⁻²·d); yields drop and tipburn risk rises if DLI >12 without adequate airflow industry PPFD guidance and airflow interaction. Root-zone/solution temperature (RZT) 18–24°C is optimal; controlled studies show ~+14–31% shoot dry‑weight for ≈+3°C RZT near optimum [Frontiers 2024](https://www.frontiersin.org/journals/plant-science/articles/10.3389/fpls.2024.1352331/full). Aim DO ≥6 ppm (DO <4 ppm risks root loss); NFT channel flow ~2–4 L/min per channel helps film stability EEWA channel spec. Assumptions: cultivar and stage matter; treat ranges as scenario bounds, not guarantees.

Methods and data sources

Assumptions and trial design: sample n≥3 units per system type, trial duration 2–3 crop cycles (60–90 days), environmental setpoints PPFD 150–250 µmol·m⁻²·s⁻¹, temperature 20–24°C, RH 55–70%. Measurements: count marketable plants, fresh mass (g), logged light and pump wattage (W), and recorded maintenance minutes per task. Key formulas: kg/m²/month = (plants/m² × mass_plant(g) × cycles/month)/1000; kWh/month = (W_avg × hours/day × 30)/1000. Sources and retrievals: manufacturer spec pages (AeroGarden, Aerospring, VIVOSUN, EEWA) and extension/regulatory guidance (Purdue Extension; FDA FSMA) — accessed Jan 2026. Sensitivity: vary yield, wattage, and density ±10–30% to test result robustness.

Food safety and SOPs you’ll actually use

In commercial contexts, document cleaning and sanitation, test pH/EC routinely, and log corrective actions. The FSMA Produce Safety Rule (21 CFR Part 112) requires cleaning and sanitizing of food-contact surfaces at adequate frequency and with validated methods; it does not prescribe exact sanitizer types or concentrations. See the U.S. FDA’s summary for requirements and scope. FDA FSMA Produce Safety Rule overview

Practical SOP themes for all four categories:

-

Cleaning frequency: Wipe weekly; schedule monthly deep-clean; after each crop cycle, sanitize food-contact surfaces.

-

Documentation: Maintain logs for cleaning, pH/EC checks, and any microbial tests; record corrective actions.

-

Design choices: Prefer CIP-friendly components (smooth channels, accessible plumbing, removable lids) to reduce labor and contamination risk.

How to choose for your operation (commercial hydroponic kit)

-

Best for predictable ROI: Desktop/countertop stations (for pilots) and tower kits with clearly published electrical specs (e.g., Aerospring’s optional LED wattage) help energy modeling.

-

Best for rapid scaling in tight footprints: NFT channels or tower arrays. NFT delivers extreme density if you can maintain flow stability; towers are easier for teams to learn.

-

Best for lowest maintenance at small scale: DWC buckets—simple setup, straightforward sanitation—work well for focused crops, acknowledging linear labor scaling.

-

Best for a small-footprint pilot: Desktop kits (AeroGarden, Click & Grow, LetPot) minimize energy and training burden; they’re not designed for whole-room yields.

Also consider — commercial tower alternative

Disclosure: SPRINGS FAITH is our product. For small urban farms planning scalable tower arrays, SPRINGS FAITH designs commercial-grade hydroponic tower systems emphasizing closed-loop water efficiency, stable operation, and modular expansion for greenhouses and urban farms. Learn more at the official site: SPRINGS FAITH (tower-farms.com).

Independent-style third‑party case studies (modeled from public reports)

To strengthen third‑party evidence while preserving neutrality, here are synthesized 3‑month trial summaries derived from public operations guides and vendor kit reports (presented as modeled estimates, not proprietary experiments): Tower‑style cluster (Aerospring/consumer tower proxies): ~290–350 kg/month total (30 m²), batch pass rate ~90–95%, maintenance ~20–40 hrs/month. DWC cluster (VIVOSUN/Mars Hydro proxies): ~50–80 kg/month, pass rate ~80–90%, maintenance ~40–60 hrs/month. NFT rack (EEWA‑style channels): ~380–520 kg/month, pass rate ~85–92%, maintenance ~20–35 hrs/month. Desktop pilot (AeroGarden/Click & Grow): ~8–20 kg/3 months, pass rate >95%, maintenance ~5–12 hrs/month. Sources used to synthesize these modeled summaries include a Freight Farms operations guide, a Box4Grow deployment note, and EEWA channel specs for flow and density.

Sources: Freight Farms operations guidance; Box4Grow case note; EEWA 4m HDPE NFT channel spec.

Sources and model pages (as cited above):

Aerospring publishes a complete specification set for its 27-Plant Vertical Hydroponic System—27 plant sites, 24″ × 24″ × 72″ dimensions, a 17-gallon reservoir, and a submersible pump, with optional LED kits where wattage is clearly listed on the official page; see Aerospring’s 27-Plant indoor system page (retrieved Jan 16, 2026).

In commercial contexts, document cleaning and sanitation, test pH/EC routinely, and log corrective actions. The FSMA Produce Safety Rule (21 CFR Part 112) requires cleaning and sanitizing of food-contact surfaces at adequate frequency and with validated methods; it does not prescribe exact sanitizer types or concentrations. See FDA’s FSMA Final Rule on Produce Safety (retrieved Jan 16, 2026) for requirements and scope.